RAP Declaration Module

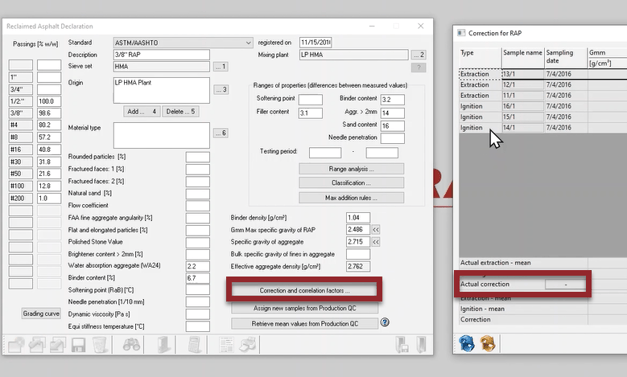

To calculate an offset for gradation and binder content, use the correlation correction factors button to pull in extraction and associated ignition tests. Use the actual correlation button to change the sign to match local standards.

Asphalt Declaration Module

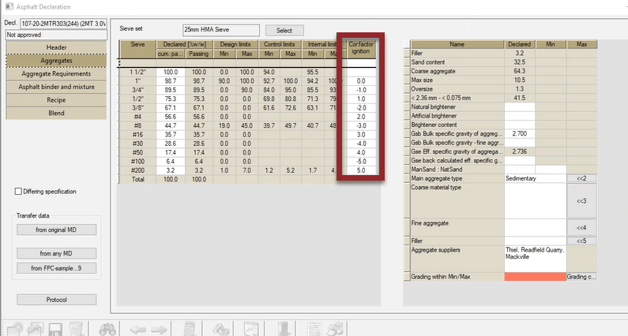

Define an ignition oven correction factor for every mix at every plant, either one correction per mix design or unique corrections for each plant.

Asphalt QC Module

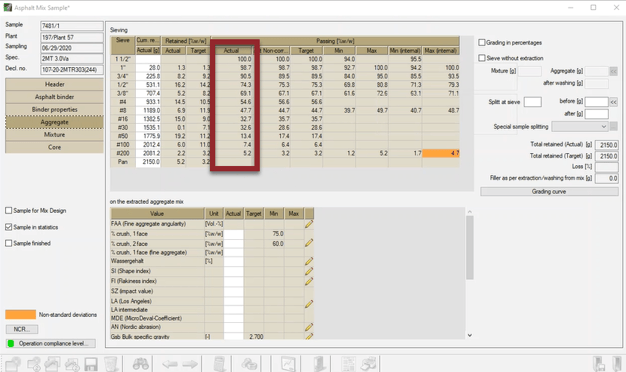

LASTRADA takes the asphalt content by ignition and aggregate gradation from a recovered sample and applies the appropriate correction factor.

LASTRADA's declaration structure makes it easy to keep track of your ignition calibrations. LASTRADA has various modules to organize your mix designs, RAP stockpiles, and ignition oven calibrations.

For more information on how LASTRADA helps asphalt producers, visit our asphalt solutions page.

VIDEO TRANSCRIPT:

The ignition oven is a great tool for recovering aggregates from hot mix asphalt. To perform a gradation some

specifications require you to understand the precise influence of the ignition oven on gradation prior to and during production.

In this Lightning Demo, I'll show you how LASTRADA applies and manages ignition oven correction factors to both asphalt mixes and rap stockpiles. Here we are in LASTRADA wrapped declaration and we have a button here called correlation correction factors. Where we can pull an extraction and associated ignition tests in the software will calculate an offset for both gradation and binder content for us. We even have a button here to change the

sign when we're making a report so it matches our local standards.

On the asphalt mix side, we have the ability to find an ignition of and correction factor for every mix at every plant.

Therefore, we can have one correction factor for every mix design or we can have unique ones at each plant where we may have individual ignition ovens. Now, when I'm in the Asphalt QC module and my sample has both an asphalt content by ignition and an aggregate gradation from a recovered sample LASTRADA is going

to take this actual non-corrected gradation and it's going to apply the appropriate correction factor that we

assigned to this particular product at this plant.

For more information about how LASTRADA can simplify your work check out our other Lightning Demo

videos www.lastradapartners.com/resources or visit our contact page to speak with one of our engineers.