Testing from the Perspective of an Asphalt Plant Receiving Binder

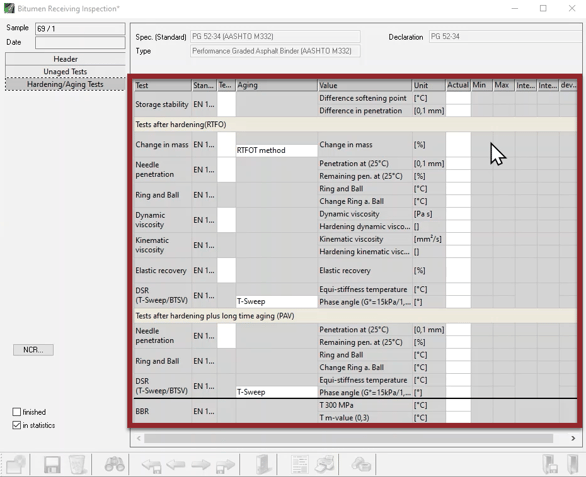

Log asphalt binders, select products, and perform binder tests in the Bitumen Receiving Inspection module.

Testing from the Perspective of a Production Facility

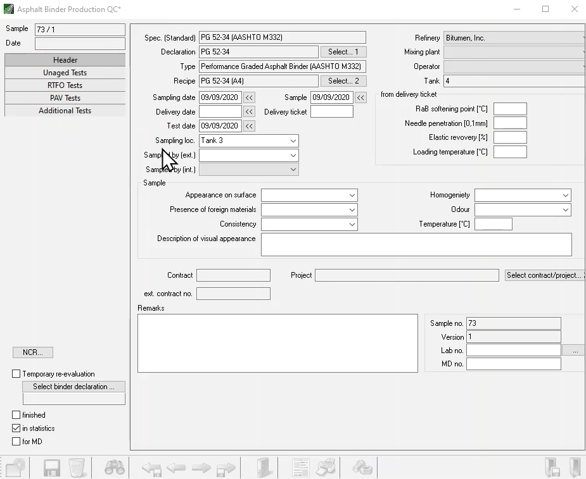

Add your sample and header data before performing tests from the Asphalt Binder Production QC module.

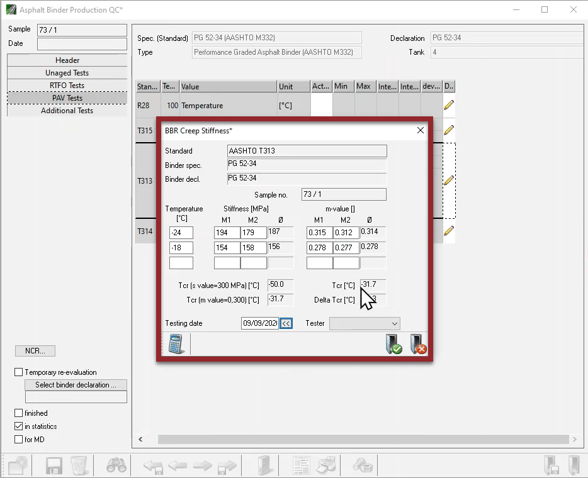

LASTRADA calculates binder properties when you enter test data and hit the calculator button. This test is looking at delta TC.

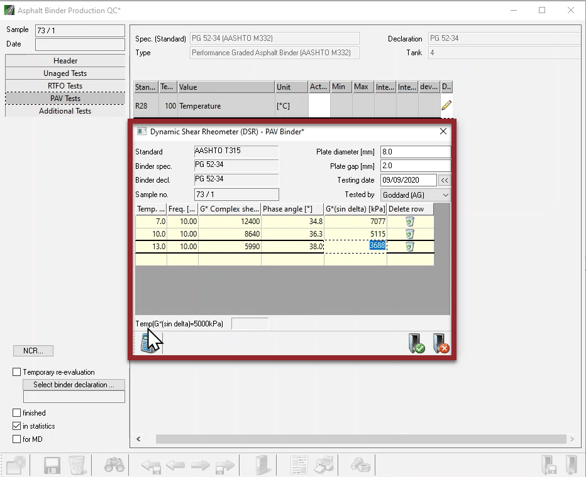

LASTRADA can also determine your intermediate cracking temperature when you log your data and hit calculate.

Move towards a balanced mix design in performance testing by utilizing LASTRADA's modules and testing functions to record data and run tests.

VIDEO TRANSCRIPT:

The asphalt industry is moving towards a balanced approach to mixed designs using performance testing. These performance tests are highly influenced by the properties of asphalt binder having Delta TC critical intermediate temperature and other binder properties stored in separate locations or spreadsheets creates a barrier to modeling the influence of these binder characteristics on mixed performance. You're forced to perform tests in one spreadsheet and run analysis in another. Inefficiently copying information from both. In this Lightning Demo, we'll show you how LASTRADA natively supports testing of these important binder properties and stores it ready for use in your balanced mix design analysis.

Asphalt binders in LASTRADA can be tested from two perspectives. The first perspective is received binder to an asphalt plant, so I can log asphalt binders I can select a product that we have available to that plant, and then I can do my tests on that binder.

Binders can also be tested from the perspective of the production facility I'm going to take that perspective for this demo. I'm adding a new sample. I've added relative header data to the sample and now we're going to go ahead and enter our test data.

Once I enter my test data LASTRADA calculates Delta TC for me. Now, let's go look at T intermediate. To have LASTRADA determine our intermediate critical cracking temperature we open our test dialog and we enter our data. Once all our data is entered LASTRADA will calculate the critical temperature for us. In the intermediate critical cracking temperature for this sample is 10.2 degrees C.

For more ways, LASTRADA can simplify your work, check out our other Lightning Demo videos at www.lastradapartners.com/resources, or visit our contact page to speak with one of our engineers.