We have spoken with a few hot mix asphalt (HMA) producers who use the Troxler moisture management system to measure the aggregate moisture content of feed aggregates real-time just prior to addition into the aggregate dryer. After reading the information about the MMS and speaking to MMS users, we are intrigued about the ability of the MMS, as part of a plant control or quality control system, to improve mix consistency from an HMA plant. We also believe that continual analysis of MMS data through a software product like LASTRADATM or Microsoft Excel can be used to indicate aggregate feed consistency, indicating ineffective air cannons, insufficient individual aggregate feed rate, and stockpile segregation. Disclaimer, this last part is our think not necessarily that of Troxler’s.

LASTRADA Partners is of the opinion that its data can be analyzed—using a software application like LASTRADA™ or Microsoft® Excel®—to track aggregate feed consistency, identify ineffective air cannons and/or insufficient individual aggregate feed rate, and detect stockpile segregation.1

We have invited Troxler to provide information about their system to our clients and contacts.

1 - This statement is the opinion of LASTRADA Partners.

Troxler Moisture Management System (MMS™)

Accurate aggregate dry weight data provides hot-mix asphalt (HMA) plant operators with the means to more closely match binder asphalt binder addition rate actual to actual aggregate moisture content. Having access to the aggregate moisture content of the dryer allows operators to produce hot mix asphalt at a more consistent binder content and mix temperature. Consistency means more precise burner temperature control during drying thus saving energy and reducing greenhouse gas emissions, enhance product quality/pavement performance thus increasing bonus potential, and nearly eliminating binder over addition which saves money.

“The real aggregate moisture contents of the materials are constantly changing throughout the day due to a number of different causes,” according to Malcolm Swanson of Astec. – Asphalt Magazine, Summer 2017. Troxler has introduced a real-time Moisture Measurement System (MMS™) (Model 3630). for quality-oriented asphalt drum plants. Hot plant operators will improve their mixture consistency and more precisely control binder addition using the actual aggregate moisture content on the belt to determine asphalt binder addition rates with the MMS. Increasing the precision of asphalt binder addition will reduce waste and asphalt cost.

Depending on the throughput of a plant, the payback period for an MMS is about 6 months.

What is the MMS?

The Troxler MMS is a non-contact solution that can be integrated with your plant’s control system, allowing asphalt producers to focus on what they do best, making high-quality asphalt by improving the precision of asphalt binder addition.

There is no physical contact with the aggregate mix or belt. The system provides a continuous reading of the aggregate moisture content as the aggregate moves through the plant on the conveyor belt. An MMS system includes Troxler’s proven nuclear moisture and density measurement technology. The MMS measures any virgin aggregate feed on a moving conveyor belt with minimum 2” material depth. Real-time moisture measurements are displayed in the control room or directly transmitted to a plant control system through integration. The MMS sends a standard signal as a current or voltage which easily integrates with plant control systems for complete

The real-time moisture along with the weigh bridge data allows plants to make asphalt more like the mix design than ever before.

Current Moisture Readings vs. MMS?

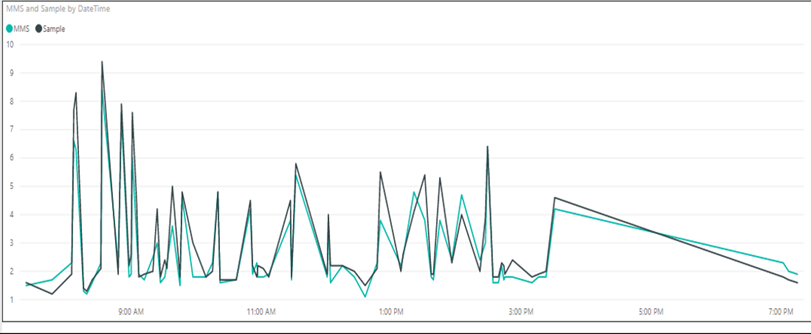

This graph highlights the accuracy of the MMS, and it shows how much the aggregate moisture content fluctuated over the course of one day. In 12 hours, the moisture went from 1.5%to 9.5% to 2.0%, which means this plant would have metered significantly more binder than was necessary without the MMS.

Nuclear Licensing.

If you’re hesitant because of the hassle of nuclear licensing, Troxler handles the general license with the NRC. Since the MMS is generally licensed, that also means no badges, no RSO, and no paperwork. Additionally, where moisture probes in the bin break often and only measure what they can touch, the MMS doesn’t touch the aggregates as they pass under the readers on the virgin aggregate belt, so it’s a set-it and forget-it enhancement to your operations.

Why Troxler?

Since 1958, Troxler Electronic Laboratories has provided the transportation construction industry with the best in precision quality control. Troxler equipment is with you in the lab and on the road, and we know density. Troxler nuclear gauges are the industry standard – This proven nuclear technology used to better control field operations is available to better control asphalt production.

For asphalt plants, knowing the correct dry weights of aggregate allows more precise mixing, resulting in savings by nearly eliminating wasted binder. Additionally, knowing the aggregate moisture content of the mix entering the drum results in better performing asphalt leading to less remove and replace or reduced pay scenarios. Depending on the throughput of a plant, the payback period is about 6 months.

For more information about the MMS, visit http://www.troxlerlabs.com/products/details?prodid=47 today.

About Troxler Electronic Laboratories, Inc.

Since 1958, Troxler has been the worldwide leader in precision quality control and measurement equipment and instrumentation for the highway and construction industries. We are dedicated to providing premier service, maintenance, and training for all our products through our international sales and support offices in the United States, Canada, China, and Germany and over forty distributors around the world. How can we help you? Call us at 1-877-TROXLER or visit www.troxlerlabs.com today.