ROADS ARE VITAL FOR DEVELOPMENT and GROWTH

Cities, states and metropolitan areas throughout the United States rely on the transportation network as the pulse of the economy. By linking producers to markets, workers to jobs, students to schools, and the sick to hospitals, roadways are key to promoting growth and development. The vital impact of the transportation network is observed through the historical construction of infrastructure such as railroads and how that coincided with periods of rapid economic growth in the United States, Western Europe and Japan. Highway pavements are essential for the safe, comfortable and rapid transportation of people and goods. Therefore, they should be, amongst other things, durable, able to withstand the elements i.e. scorching sun, freezing temperatures and protect the base from the rain and snow; whilst efficiently transmitting traffic loads to the road-base and underlying soil.

BUILDING THE ROADS REQUIRES A NEW TESTING APPROACH; OLDER WAYS NO LONGER SERVE

Increased traffic volumes, vehicle loads and changes to bitumen properties plus developments in pavement materials such as the use of polymer modified bitumen, recycled asphalt, recycled tyre rubber and marginal materials have resulted in significant changes to asphalt mix design and pavement performance. Traditional, empirical, design and testing methods do not evaluate how asphalt mixtures (mixes) are affected by traffic speed and climatic conditions and fail to properly evaluate pavement performance against real-world conditions. In addition, they do not establish the fundamental materials properties needed for inputs into sophisticated pavement design models for creating optimised pavements. Inadequate characterization of pavement materials leads to sub-optimum pavement design. This may result in costly over-engineering, early pavement failure, with the consequent additional construction and reconstruction costs; plus increased traffic disruption, fuel consumption, accidents, road trauma and vehicle wear and damage.

Asphalt is a complex viscoelastic material; whose mechanical properties change under different loading frequencies (traffic speed) and temperature conditions (climate). Therefore, proper characterization of mix response to different real-world loading and environmental conditions is critical to predicting performance over the life of the pavement.

Traditional materials characterization methodologies, such as Marshall, are rudimentary empirical tests. Although they have historically served the industry well, changes as highlighted above mean their simplistic assumptions that materials behave consistently regardless of environmental or traffic conditions are no longer appropriate. In addition, traditional tests do not measure the fundamental properties of materials necessary for input into the sophisticated optimized pavement designs models.

In contrast, performance-based testing defines how different mixes will perform within a pavement structure under an infinite combination of environmental and traffic conditions. Understanding this and therefore the mix’s full fundamental response characteristics is imperative to ensuring optimum pavement performance.

The use of inadequate and invalid characterization techniques of new pavement materials can lead to sub-optimum pavement design that may result in either costly over-engineering or early road failures which will require repair or reconstruction. The consequences of which will be additional costs of construction and/or reconstruction as well as economic consequences of traffic disruption, traffic accidents, road trauma, increased fuel consumption and increased vehicle damage. Furthermore, resources that could have been allocated to the development and construction of new roads may have be diverted to higher than necessary construction costs, repair, reconstruction and maintenance costs.

Modern optimized designs therefore, aim to engineer long lasting, high-performance pavements, that will resist wheel track rutting, fatigue and thermal cracking and maintain excellent surface roughness essential for safe and comfortable passage of vehicles, and avoid both premature failures and excessive costs. Pavements, must therefore, be designed to strict performance parameters.

For appropriate and optimum inclusion of new mixes in the design, especially after the introduction of recycled materials such as reclaimed asphalt pavement (RAP) and recycled asphalt shingle (RAS), pavement designers need to know their performance and fundamental physical properties. However, the research results available, are often only, for specific bitumen and aggregate, with new materials either untested or not fully characterised. And without the right techniques and tools, it will be impossible for pavement engineers to maximize the benefits of the new materials and design optimum high-performing mixes and long-lasting pavements.

High quality and accurate equipment is therefore essential to prepare specimens and perform advanced static and dynamic tests along with the adoption of performance-based mechanistic-empirical design methodologies that facilitate the correct selection of materials and optimum pavements design that deliver best value for money in terms of relative materials and construction costs versus highway quality, performance and pavement life.

DEMOCTRATIZING PERFORMANCE-BASED TESTING

Originally mix performance tests were difficult to conduct and few laboratories possessed the know-how and equipment to perform full SuperPave designs. Therefore, there was a need to develop simpler methodologies and standardized commercial testing equipment to conduct performance related laboratory tests. This was addressed in the United States with a National Cooperative Highway Research Program (NCHRP) project, that led to the development of Asphalt Mixture Performance Tester (AMPT) previously called Simple Performance Tester (SPT), as the reference machine for accurate characterising asphalts for performance-based pavement designs. NCHRP 9-19 and 9-29 projects had the specific purposes, the former was tasked with determining the fundamental laboratory tests that best correlated with real-life mix performance in the field; and the later developed a clear specification for an affordable instrument that will quickly, easily, accurately and repeatably perform those tests and facilitate its adoption by highway agencies, asphalt producers and contractors.

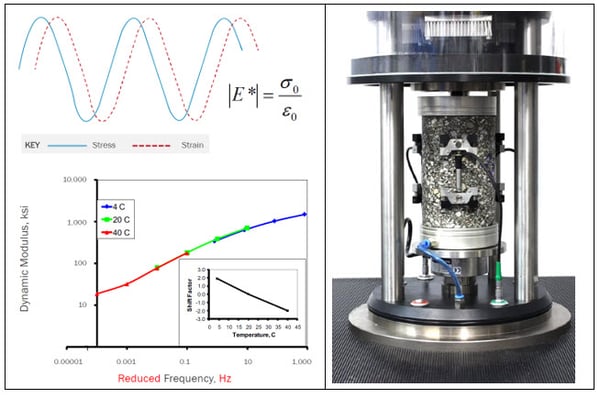

Originally the AMPT was conceived to facilitate rapid and easy determination of Dynamic Modulus E* and Flow Number/time for cylindrical asphalt specimens prepared either in the laboratory or cored from the field. Results from Dynamic Modulus E* tests performed with the AMPT Pro provide a complete characterization of the mechanical strength and stiffness behaviour of the mix evaluated under a wide range of temperatures and loading frequencies combinations. The Flow Number test provides a measure of rutting potential. These results are useful in multiple applications, ranging from pavement design to quality control purposes. Dynamic Modulus E* and Flow Number results are also fundamental inputs for the Mechanistic-Empirical Pavement Design Guide (MEPDG).

Although important, mix performance tests are only one part of the Superpave mix design process that requires the careful characterization of all the constituent materials. Also of critical importance, is the production of highest quality representative samples and specimens of testing. Because regardless of the sophistication of available testing equipment and the expertise of laboratory technicians, a poor-quality specimen will not provide accurate measures needed to give insights for correct engineering decision making.

NEXT GENERATION PERFORMANCE-BASED TESTING

The demand for affordable performance-based test equipment, to measure fundamental mix properties and simulate field performance, has led to the development of several new devices from IPC Global that quickly and easily predict the performance of mixes over a range of temperatures and frequencies. AMPTQube and AsphaltQube are a new generation of Quality Control testing machines, developed to democratize dynamic performance testing and make them accessible entire asphalt industry.

Over time other performance tests, for characterizing a wider range of mix properties, have increased in importance. For example, Semi-Circular Bend (SCB) for fracture energy and toughness, Texas Overlay cracking susceptibility, Uniaxial Fatigue (SVECD) for fatigue life and Stress Sweep Rutting (SSR) rutting tests. These new tests have significantly expanded the capabilities of AMPT Pro, AMPTQube and AsphaltQube.

Another important development has been the successful use of small diameter samples for performance testing of Dynamic Modulus E*, Flow Number and Uniaxial Fatigue SVECD tests. These specimens are either cored horizontally from the field cores or multiple vertical cores taken from a 150mm diameter gyratory compacted specimen. The specimens are typically 38mm (diameter) x 110mm (height) or 50mm (diameter) x 110mm (height). The benefits of the small diameter tests are faster production of multiple specimens, faster SVECD sample preparation due to reduced gluing time and the ability to test properties of field cores for forensic examination and Quality Control.

With the advent of more advanced pavement design modelling systems, such as the MEPDG, determining the fundamental properties of asphalt mixes using devices, such as AMPT Pro, AMPTQube and AsphaltQube, is essential for reducing uncertainty, risk and by optimizing performance-based pavement designs.

Thanks to these systems, proper asphalt characterization can now easily become a routine practice at all industry levels, not only because the tests are simple and easy to execute, but because affordable equipment is now available to perform the tests.

CONCLUSION and LEARN MORE

Having the ability to properly characterize asphalt performance becomes even more important when considering the regular introduction of new materials and design techniques. In order to properly assess and maximize the benefits of these new materials and technologies, deep analyses with the appropriate equipment is now fundamental.

Next, we will explain the many Return on Investment (ROI) benefits that will come from deep materials analysis and characterization when used as part of a SuperPave type optimized performance base pavement designs. Benefits discuss include:

- Longer lasting pavements

- Higher quality, higher performing pavements

- Reduced construction times

- Reduced maintenance costs

- Reduced congestion

- Reduced road traffic accidents

- Reduced road trauma

- Better access to education and healthcare

- Economic growth

- Reduce fuel consumption

- Reduced vehicle wear and damage

In February 2018, CONTROLS Group launched IPC Global | CONTROLS Group, an exciting new division focusing entirely on advanced testing equipment for road pavements materials e.g. asphalt mixtures and binders. The new division brought together the collective expertise, experience, products and markets in this field of IPC Global and CONTROLS Group.

With nearly 30 years’ experience as the global leader in the field of advanced dynamic asphalt testing equipment and sample preparation machines, IPC Global boasts an unrivaled experience, reputation and customer base. Now, coupled to this is CONTROLS Group’s extensive experience and expertise with their own range of advanced static and binder testing equipment. The result of this combined and united efforts is the most complete and advanced range of equipment available from any single supplier making IPC Global | CONTROLS Group a real one-stop-shop for advanced asphalt laboratories.

The combined technical expertise, market knowledge, research and industry connections have enabled IPC Global to develop a significant range of new game-changing products. Over time IPC Global has seen the market for advanced testing expand and change in a number of ways. Firstly, more mature markets have experienced an expansion of performance of these tests with them being performed, not only by high-end research laboratories, but also state highway authorities, Departments of Transport (D0Ts) and contractors. Secondly, in developing countries, there is an emerging recognition that traditional test methods and pavement designs are inadequate, and there is a need to adopt more evolved and sophisticated SuperPave type performance-based testing.

These changes have seen a demand for equipment and tests that are quicker, simpler and more affordable than equipment that has previously been the preference for researchers. To address these needs and continuing on our heritage and reputation as market leading innovators, IPC Global | CONTROLS Group has committed wholeheartedly to the development of truly group-breaking technologies that have democratized performance testing and put them within the reach of DoTs, contractors and developing countries.

A major advancement has been the development of Electromechanical Servoactuation (EmS). This new innovation allows closed-loop high frequency dynamic testing to be performed on systems without the need for hydraulics or pneumatics. EmS technology significantly reduces the complexity of installation, initial outlay, associated maintenance costs as well as delivering near silent testing systems noise; all at a much more affordable price. Major new systems include AMPTQube, a next generation QC asphalt mixture performance tester for SuperPave; AsphaltQube QC modulus system for all the main international asphalt performance tests and Galileo & Galileo Research full EmS next generation gyratory compactors that are simple to install, low cost to maintain and have market beating specifications.

Last but not least, the introduction of the new IMACS2 market leading integrated multi-axis control system and UTS Neutron next generation advanced asphalt testing software will meet the needs of every user from QC operators who need a simple interface to advanced researchers who want to develop and modify tests independently.

IPC Global and CONTROLS Group are set to continue leading the field and providing testing solutions to an ever-evolving customer base.

To learn more information about establishing a SuperPave type performance-based asphalt mixture and pavement design methodologies visit the CONTROLS Group website:

Article written by

Kieran McGrane Khaled Hasiba, P.E.

Chief Executive Officer/ Production Specialist

Marketing and Development Director